How To Extend the Life of an Industrial Concrete Floor

9th Feb 2024

Maintaining industrial concrete floors is essential for operations that rely on clean, durable, and safe surfaces. Unfortunately, the concrete floors undergo extreme wear and tear due to heavy foot traffic and equipment, leading to expensive repairs and replacements. However, taking the necessary measures can help your business extend the life of your industrial concrete floors.

Understanding Industrial Concrete Floors

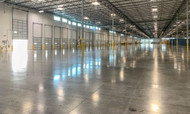

Industrial concrete floors are highly durable and suitable for use in heavy-duty environments, including factories, warehouses, and other industrial spaces. They offer various benefits, such as strength, durability, resistance to spills, and ease of cleaning. However, they are not indestructible.

The challenges industrial concrete floors face are primarily due to the heavy foot traffic and equipment movement. This traffic can cause significant wear to the surface of the concrete, such as scratches or gouges. Additionally, exposure to various substances, including oil, chemicals, or acids, can cause the concrete to deteriorate. Proactive measures are necessary to preserve the longevity of the floors.

Regular Cleaning and Maintenance

A well-maintained concrete floor can endure heavy machinery, people, and other equipment. However, ignoring surface maintenance can quickly lead to erosion, cracks, and other damage, ultimately resulting in a shorter lifespan for the flooring. Fortunately, you can implement smart practices that prevent issues.

You can extend the life of an industrial concrete floor with regular cleaning. Dirt, debris, and other contaminants can accumulate on the surface, leading to abrasion, scratching, and other forms of damage.

Choosing the Right Cleaning Products and Methods

Harsh chemicals are detrimental to the floor’s surface, causing it to erode and deteriorate. For example, acidic cleaners, bleach, or strong solvents can affect the surface. Therefore, it is essential to select non-abrasive, pH-neutral cleaning agents that will not damage the floor.

Furthermore, properly cleaning an industrial concrete floor is a vital part of extending its lifespan. To start, remove any debris or loose particles with a broom or dust mop. Then, use a pH-neutral cleaning solution to remove dirt and stains.

Once the floor is clean, consider polishing it to improve its durability and appearance. Using diamond polishing pads for concrete creates a smoother surface, reducing the risk of wear and tear. A polished floor is also easier to clean and maintain, making it a practical solution.

Routine Inspections and Repairs

Routine inspections and repairs also prolong the life of concrete floors. Address minor issues promptly, such as cracks and other surface damage, to prevent them from escalating into major problems. Timely repairs prevent further deterioration while safeguarding the floor from dirt accumulation.

You should conduct a visual examination of the concrete floor. Look for any visible signs of damage, such as cracks, unevenness, or spalling. Pay attention to areas where excessive wear and tear may occur, such as high-traffic zones or areas near heavy machinery.

By conducting routine inspections, you can identify potential issues early on, allowing for timely maintenance. This proactive approach helps ensure the overall safety and longevity of the industrial concrete floor.

Controlling Moisture and Temperature

Moisture has an impact on concrete floors, resulting in cracks, warping, and the deterioration of the surface. This occurs because concrete is a porous material that absorbs water, and it can corrode the reinforcing steel and weaken the overall strength and integrity of the concrete. Moreover, freezing water expands, leading to unsightly cracks in the concrete.

Implement proper drainage and moisture barriers to mitigate the effects of moisture on an industrial concrete floor. A proper drainage system will help channel water away from the floor’s surface and prevent it from seeping into the concrete.

A moisture barrier is a coating you apply to the concrete that stops water from penetrating it. The coating is effective in areas with high moisture levels, such as areas around machinery or near water sources.

Addressing Temperature Fluctuations

In addition to moisture, temperature fluctuations can also have a significant impact on floors. Concrete is susceptible to thermal expansion and contraction. These fluctuations can lead to cracks, warping, and other structural issues.

Install an adequate HVAC system to control temperature fluctuations. The system regulates the temperature and humidity levels within the building, preventing extreme fluctuations that can damage the concrete surface.

Ensuring proper heating and cooling system maintenance is important, as a malfunctioning HVAC system can cause sudden temperature fluctuations that may affect the floor.

Preventing Chemical Damage

Chemical spills and exposure to corrosive substances are some of the most common hazards that can damage industrial concrete floors. Without proper containment and cleanup procedures, these substances can seep into the concrete surface, causing it to deteriorate over time. Additionally, some chemicals can react with concrete, causing it to expand or contract.

When a chemical spill occurs, contain the mess to prevent it from spreading. The first step is to locate the source of the spill and shut off the supply if possible. If the material is hazardous, wear personal protective equipment (PPE) such as gloves, goggles, and respirators before handling spills.

Next, it is important to contain the spill using absorbent pads, containment booms, or berms to concentrate the mess into one area. Furthermore, the cleanup process will depend on the type of chemical you’re handling. Therefore, consult the Material Safety Data Sheet (MSDS) for specific cleanup procedures.

Educating Employees and Implementing Safety Measures

Maintaining an industrial concrete floor is not just the facility manager’s job but a collective responsibility of all employees. Educating the workers on properly caring for surfaces can minimize damage and reduce repair and maintenance costs.

Emphasizing the importance of employee awareness and training regarding floor maintenance is an ideal strategy in ensuring that the floor stays in excellent shape. During the training, discuss simple maintenance tasks, such as regular sweeping and cleaning of spills to prevent dirt, grime, and other debris from accumulating on the floor.

Additionally, demonstrate proper cleaning chemical usage techniques, such as diluting and applying them uniformly, to prevent discoloration and damage. It is also imperative to familiarize employees with the floor’s structural characteristics, such as its porosity, density, and hardness levels. Workers can use the appropriate cleaning and maintenance techniques that preserve the floor’s properties.

Finally, promoting a workplace culture of responsibility and accountability is essential. Encourage employees to report any damage, stains, or scratches immediately to the maintenance team or a supervisor. Assigning floor maintenance responsibilities to specific employees and developing a checklist of tasks ensures that everyone is aware of their responsibilities.

By taking proactive steps and staying up-to-date on best practices, businesses can maximize the value and longevity of their industrial concrete floors. Ultimately, these efforts contribute to safe and productive working environments for employees and visitors.

Need cleaning supplies? No problem. Check out our wide selection of commercial cleaning supplies today!